PROCESS & CONTROL

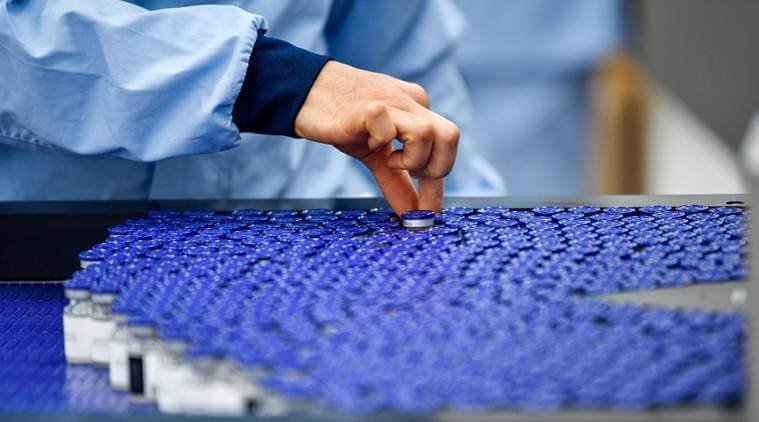

PHARMACEUTICAL & PROCESS SOLUTION

The pharmaceutical industry currently faces a major challenge in taking full advantage of the opportunities presented in large emerging markets. Now, more than ever, pharmaceutical companies need to introduce lean manufacturing techniques that will enhance profitability. As one of the world's leading industrial automation suppliers, EPSILON LIMA is committed to delivering the best possible solutions for your best manufacturing practices.

What is Pharma 4.0?

Pharma 4.0 is a roadmap developed by ISPE for the pharmaceutical industry to introduce "Industry 4.0" (also called Smart Factory).

In Industry 4.0, continuous development is aimed at improving quality and productivity, reducing costs and ensuring supply stability throughout the entire product life cycle. This is primarily accomplished by reformation of business processes through IT innovation and digitalization.

Furthermore, Pharma 4.0 needs to meet not just business performance aims and objectives, but also obligations arising from governmental regulations specific to the pharmaceutical industry.

In other words, Pharma 4.0 can be viewed as leveraging IT capabilities throughout the entire product life cycle to build quality control processes founded on ICH-Q10 Pharmaceutical Quality System (PQS) guidelines. To realize Pharma 4.0, it is essential to have IT implementation skills for digitalization and a clear vision that incorporates a detailed understanding of pharmaceutical regulations including PQS.

Why is Pharma 4.0 still required?

However, the pharmaceutical industry is caught between the increasing cost of compliance to ensure quality and the need to generate profits. To move beyond this hurdle, Pharma 4.0 implementation can be of great benefit.

Effective, efficient, and continuous quality improvement efforts based on scientific evidence are necessary (i.e.,POS) throughout the pharmaceutical life cycle and according to that defined in the ICH-Q12 Product Life Cycle Management (PLCM) guidelines. As a consequence, the compliance cost for quality assurance continues to increase in the pharmaceutical industry. And in parallel, the industry climate of worsening returns in drug discovery has forced an increased need to extract productivity gains that often include the drug manufacturing process.

To address this idea, the pharmaceutical manufacturing industry has chosen to intensify industrial automation (i.e. Pharma 4.0) and drive business reform through digitalization and in full compliance with pharmaceutical regulatory standards.

BUSSINESS SOLUTION

Continuously since the 1980s and based on a strategic focus of measurement, imaging, analysis, diagnosis and integration; EPSILON LIMA has offered manufacturing control systems and numerous instruments that support pharmaceutical production processes for active pharmaceutical ingredients (API), drug formulations, and biotechnology applications, Since 1990s, we have been working on [Industrial Automation] of production in order to realize safe and efficient production by linking the vast amount of information obtained from equipment scattered in the factories and providing various solutions of production management for the utilization.

Beginning around the same time, EPSILON LIMA began also providing live cell imaging solutions that used novel confocal microscope technology to the field of drug discovery and cutting-edge medical research.

By integrating and deepening our core technologies and experience, EPSILON LIMA is developing safer and more efficient autonomous production systems that meet the needs of the pharmaceutical industry, allowing professionals more opportunity to apply uniquely human capabilities such as creativity and innovation to the work-place.

Autonomous production systems will also reduce the reliance on human judgement for decisions regarding pharmaceutical manufacturing, quality testing, documentation and release, thus providing greater consistency and time for staff to focus on higher-level productivity efforts.

We have defined this industry "world-view" as Bio Industrial Autonomy (BIA) and made its realization a mission of the EPSILON LIMA pharmaceutical business organization.

Thus, we will contribute to Pharma 4.0 through the implementation of BIA.

Effects of Pharma 4.0 Implementations

Producers in the specialty and fine chemical market face many challenges. Research driven innovation and the rapid introduction to market of products to meetAn advanced network that connects information obtained from research, development, and manufacturing will provide a variety of positive effects by enabling complementary utilization of information from each department.

As an example, the concepts of Quality-by-Design (QbD) and Continuous Production can be enabled for new drug development and manufacturing processes. These can have the following effects:

- An early identification of Critical Process Parameters (CPP) and Design Space (DS) through data analysis.

- Monitoring of Critical Quality Attributes (CQA) by using Process Analytical Technologies (PAT) such as soft sensors.

- Promotion of Real-Time Release Testing (RTRT) of intermediates or finished products by Critical Quality Monitoring.

- An enhanced understanding of product characteristics and manufacturing processes based on accumulated data.

- Rapid response time to abnormalities and deviations based on data-driven risk assessment by improving accessibility to data

- Continued process improvement through feedback and reduction of time and costs involved in developing new drugs and manufacturing processes.